Conductive Properties of High Power DWDM DFB Fiber Coupled Laser Diode: Ensuring Efficient Performance

High power DWDM DFB fiber coupled laser diodes play a critical role in various applications, including telecommunications and data transmission, as well as industrial and scientific endeavors. These laser diodes offer high power output and wavelength selectivity, making them an indispensable component in modern communication systems. However, to ensure their efficient performance, it is crucial to understand and optimize their conductive properties. This article explores the significance of conductive properties in high power DWDM DFB fiber coupled laser diodes and highlights the factors influencing their conductivity.

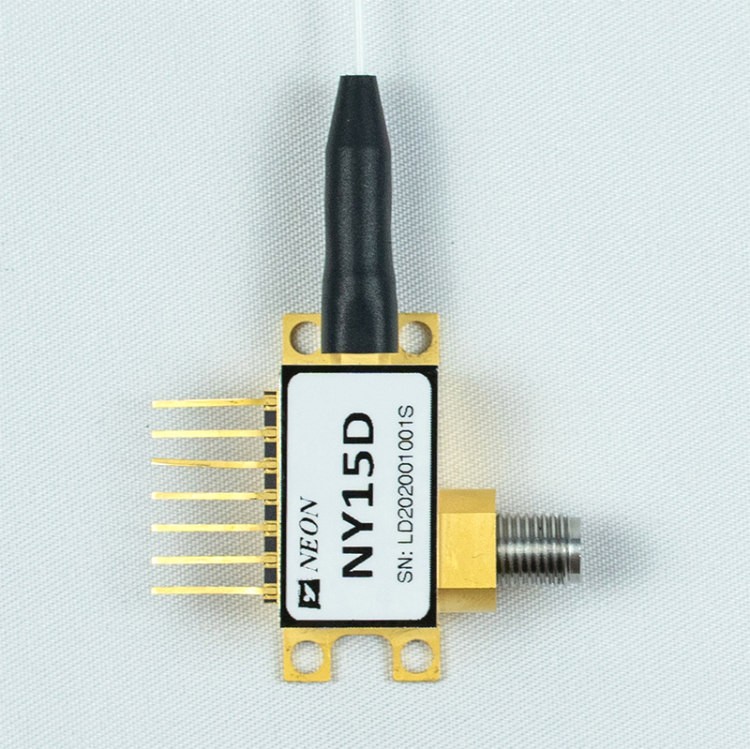

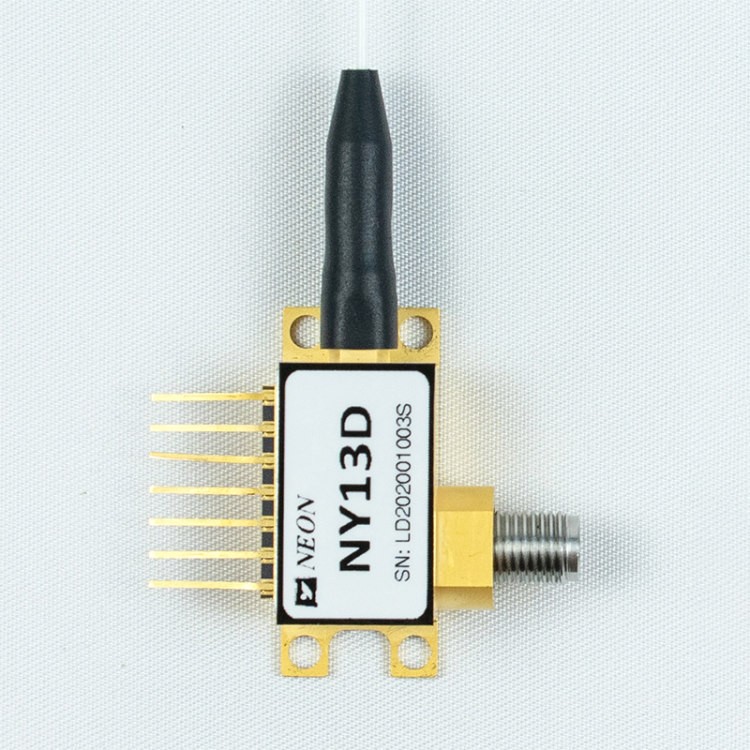

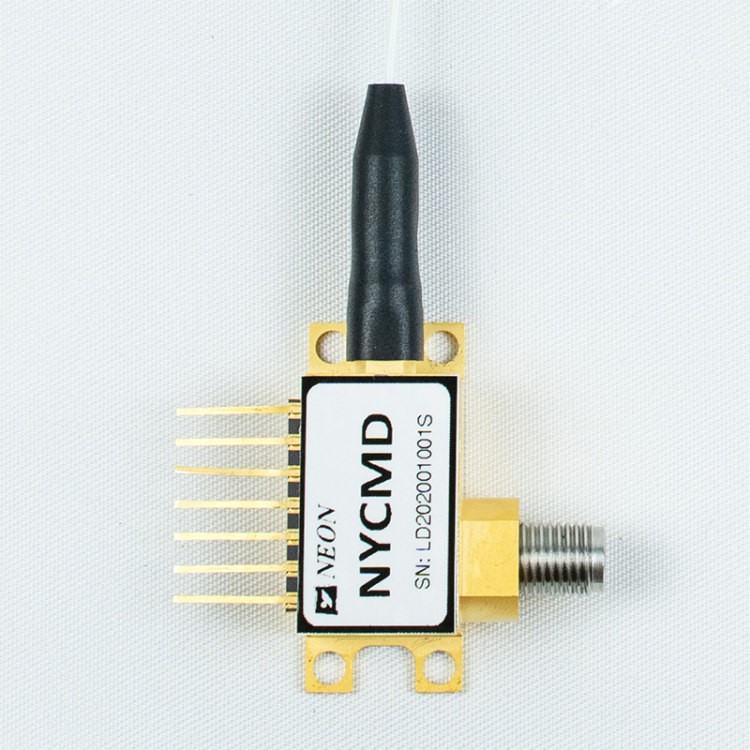

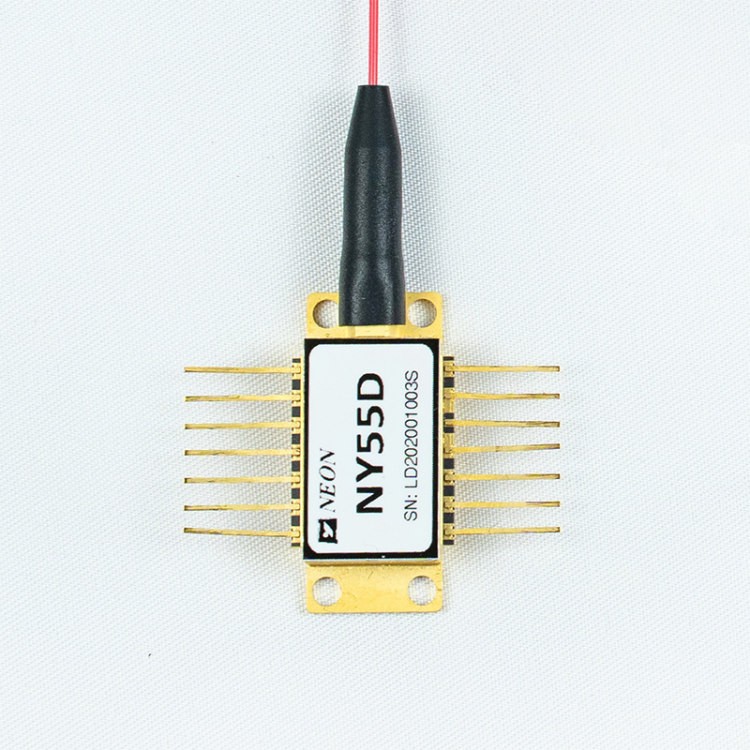

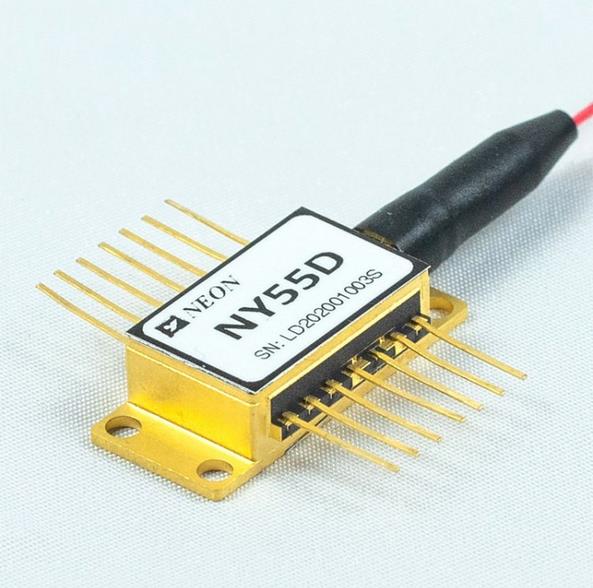

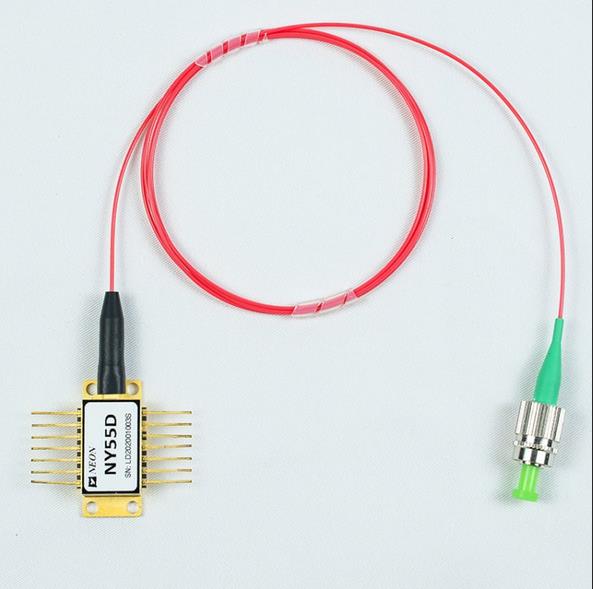

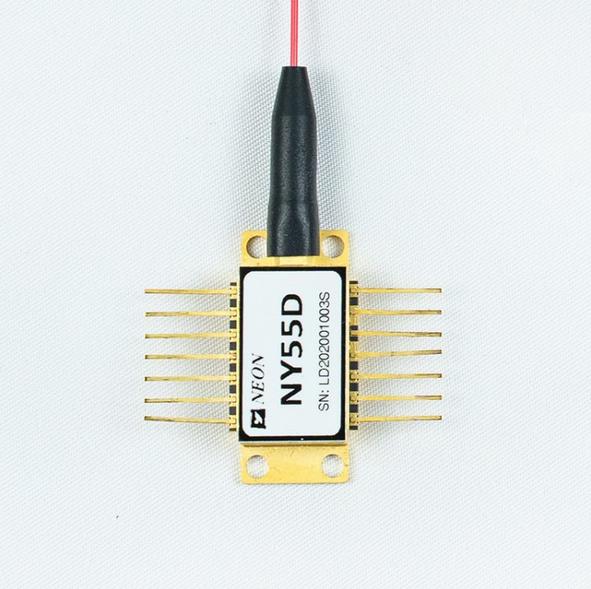

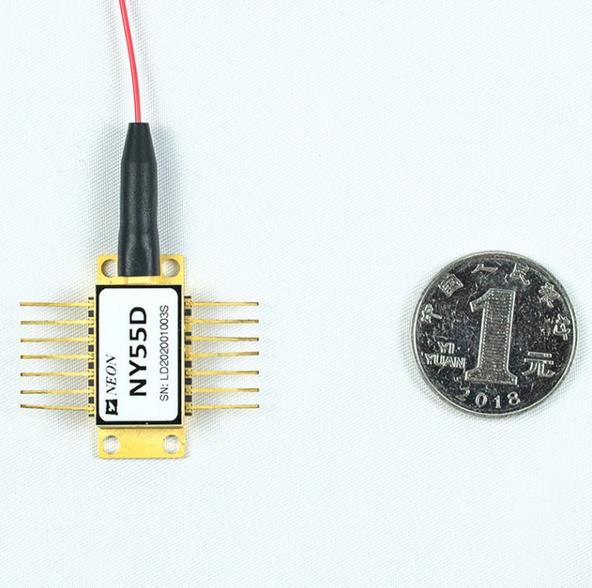

Overview of DWDM DFB Fiber Coupled Laser Diode

High power DWDM DFB fiber coupled laser diodes combine two important technologies: Dense Wavelength Division Multiplexing (DWDM) and Distributed Feedback (DFB) laser diode technology. DWDM allows multiple wavelengths to be transmitted simultaneously over a single optical fiber, greatly increasing the data-carrying capacity. DFB laser diodes, on the other hand, offer stable, single-mode operation with high spectral purity. Fiber coupling ensures efficient light transmission between the laser diode and the optical fiber, maximizing signal quality and transmission distance.

Conductive Properties of High Power DWDM DFB Fiber Coupled Laser Diode

- Electrical Conductivity

In high power DWDM DFB fiber coupled laser diodes, electrical conductivity is crucial for the flow of current within the device. The choice of materials for the laser diode structure significantly impacts electrical conductivity. Low resistance pathways are essential to minimize resistive losses, ensuring efficient power transfer and reducing heat generation.

- Thermal Conductivity

High power laser diodes generate substantial amounts of heat, which can affect their performance and reliability. Efficient thermal management is crucial to dissipate this heat. The laser diode package should be designed to facilitate heat dissipation, preventing temperature rise that could degrade the device. High thermal conductivity materials and integrated heat sinks aid in maintaining optimal operating temperatures.

- Optical Conductivity

The optical conductivity of high power DWDM DFB fiber coupled laser diodes refers to their ability to efficiently couple light into the fiber. Proper alignment and packaging techniques minimize losses, maximizing the amount of light transmitted through the optical fiber. The optical conductivity directly affects the transmission distance and signal quality, making it essential for reliable communication systems.

Factors Affecting Conductive Properties

- Material selection

The choice of semiconducting materials for laser diode fabrication is critical. These materials should exhibit low resistivity for efficient electrical conductivity and high thermal conductivity for effective heat dissipation. Advances in material science contribute to the development of more conductive and thermally efficient laser diodes.

- Design considerations

The layout and configuration of the laser diode package play a crucial role in optimizing conductive properties. Integration of heat sinks, temperature control mechanisms, and effective alignment techniques contribute to improved electrical, thermal, and optical conductivity.

- Manufacturing processes

Precision fabrication techniques ensure the reliable conductivity of high power DWDM DFB fiber coupled laser diodes. Quality control measures during the manufacturing process help achieve consistent performance and minimize variations in conductive properties.

By focusing on electrical conductivity, thermal conductivity, and optical conductivity, manufacturers can create laser diodes that offer improved efficiency and reliability. The selection of suitable materials, design considerations, and precise manufacturing processes play a vital role in achieving optimal conductive properties. As technology continues to advance, the development of laser diodes with superior conductive properties will contribute to the growth of telecommunications, data transmission, and various industrial sectors.

The future holds promising possibilities for high power DWDM DFB fiber coupled laser diodes. Overcoming resistance and thermal limitations, advancements in materials, and innovative packaging technologies will further enhance their conductive properties. Improved power efficiency, reliability, and performance will propel these laser diodes to new heights, enabling faster data transmission, longer transmission distances, and expanding their applications across various industries.

Conclusion

In conclusion, understanding and optimizing the conductive properties of high power DWDM DFB fiber coupled laser diodes are essential for their efficient operation. Through continuous research and development, these laser diodes will continue to evolve, driving advancements in communication and industrial technologies, and shaping the future of high-speed data transmission and scientific endeavors.