Enhancing DML Laser Efficiency: Key Factors and Optimization Techniques

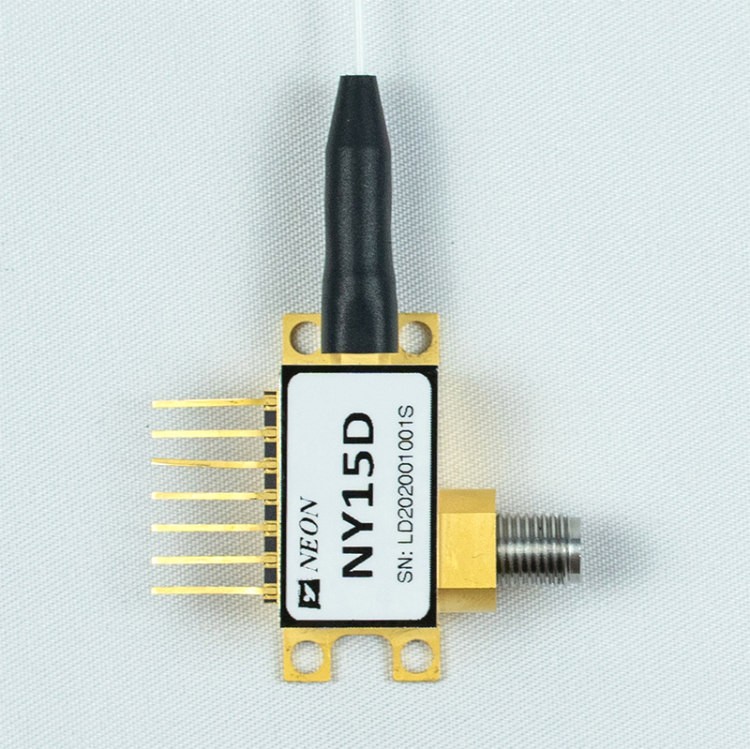

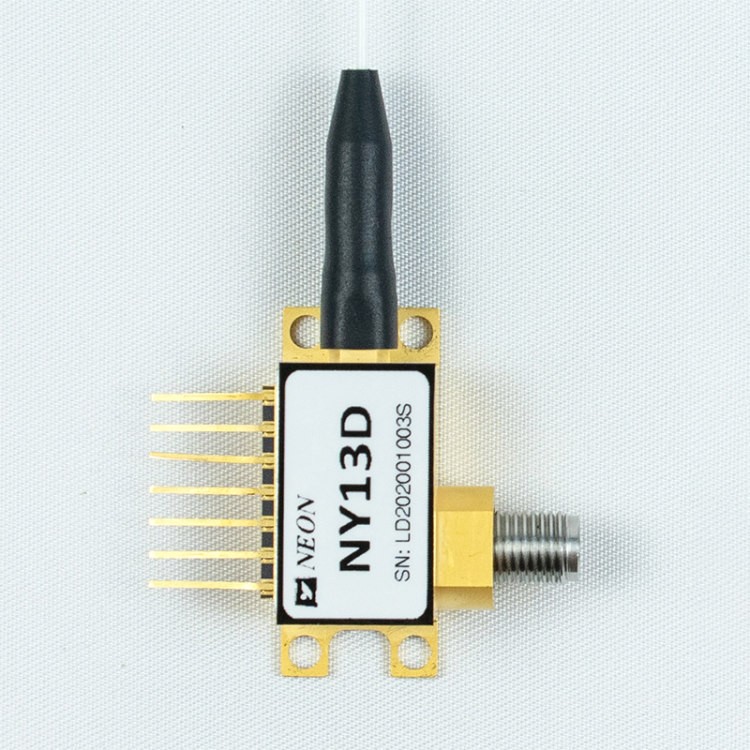

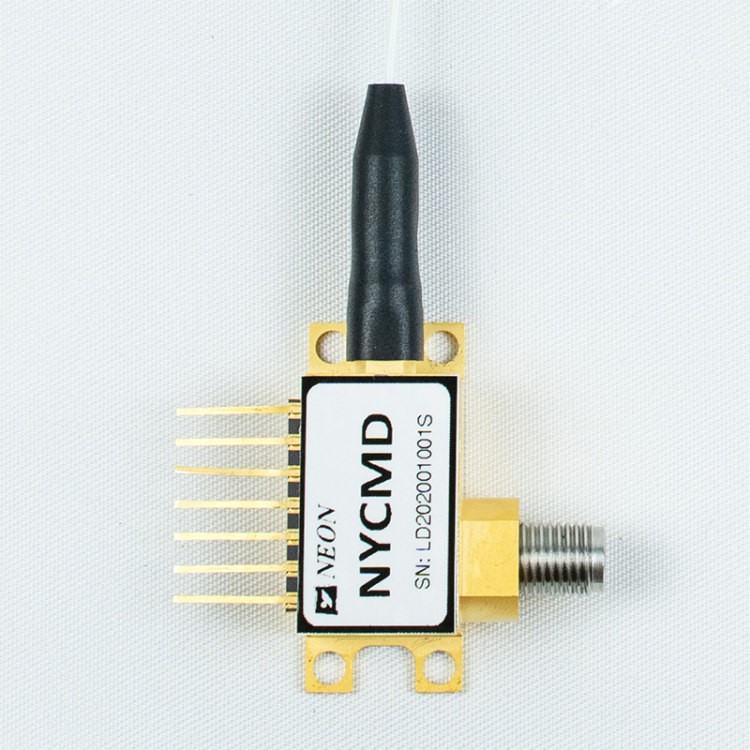

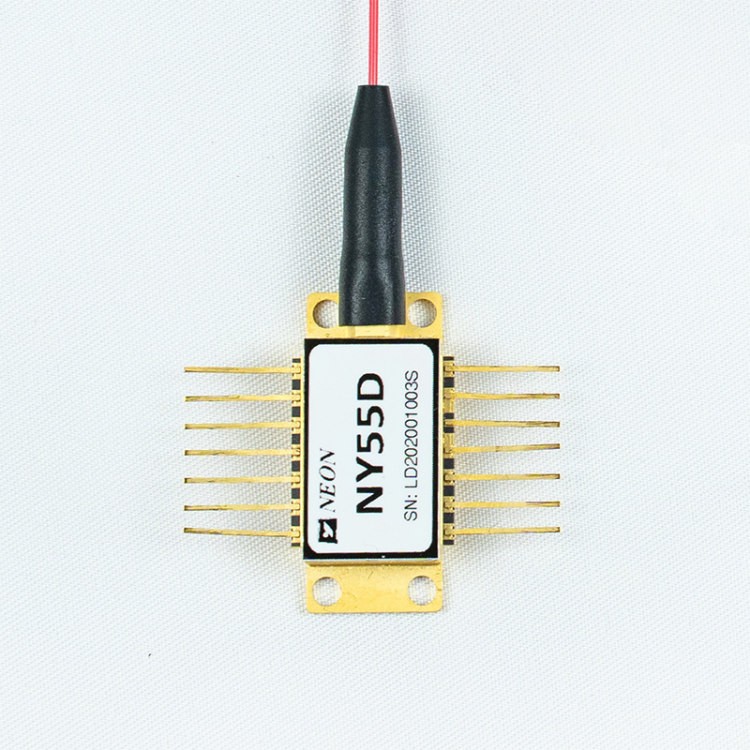

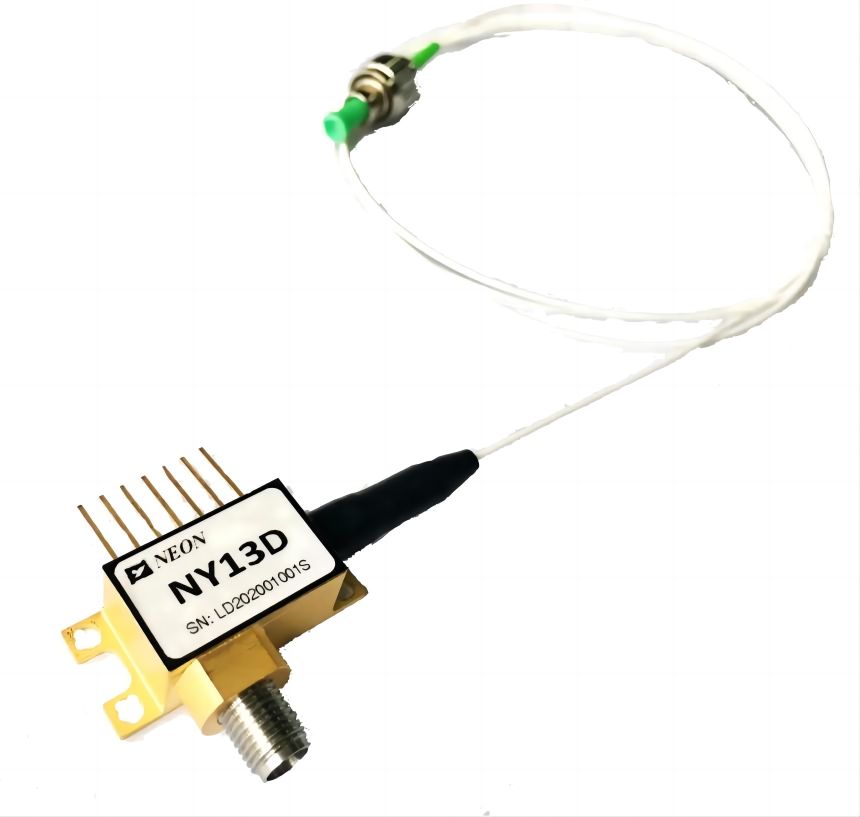

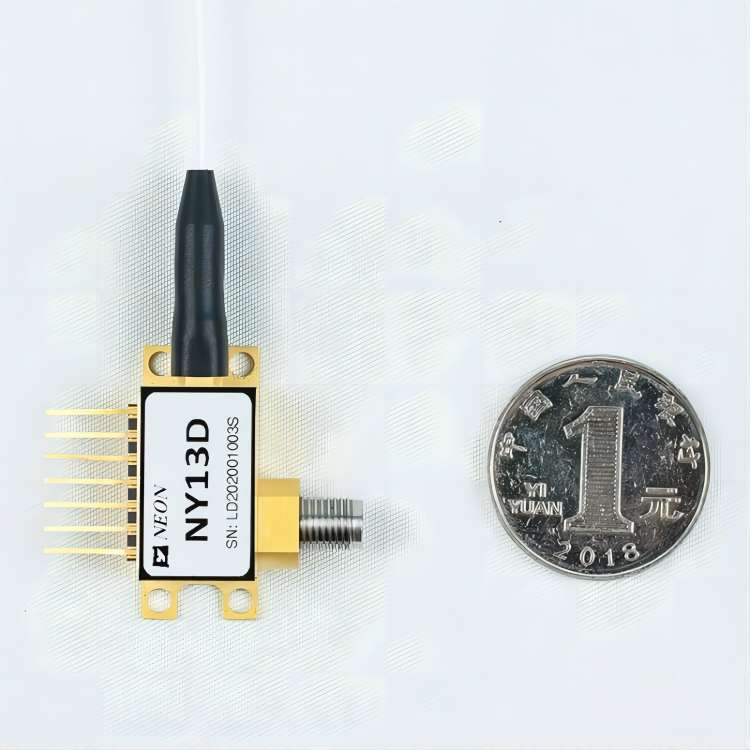

Lasers, as pivotal optoelectronic devices, play an indispensable role in various fields, including communication, medical treatment, and industrial processing. Directly modulated lasers (DML lasers), with their simple structure, low cost, and ease of integration, have found widespread applications in short-distance optical fiber communication, LiDAR, and other areas. However, transmission efficiency remains a critical factor that limits the performance of DML lasers. This article delves into the primary factors affecting the transmission efficiency of DML lasers and proposes corresponding optimization strategies.

Basic Concepts of Transmission Efficiency in Directly Modulated Lasers

Transmission efficiency refers to the ratio of the laser’s output optical power to its input electrical power (or pump power), reflecting the efficiency of the laser in converting input energy into optical energy. Enhancing transmission efficiency not only reduces energy consumption but also improves the output power and stability of the laser. The factors influencing transmission efficiency are complex and diverse, involving laser materials, structures, and operating conditions.

Main Factors Affecting Transmission Efficiency of Directly Modulated Lasers

Based on the degree of influence, the following factors are ranked and analyzed in detail:

1. Laser Material Characteristics:

- Gain Characteristics of Laser Medium: Parameters such as the gain coefficient and excited state lifetime of the laser medium directly determine the efficiency of laser generation. High-gain media can achieve higher output power and transmission efficiency. For instance, in semiconductor lasers, quantum well structures can enhance the gain coefficient, thereby improving efficiency.

- Material Loss: Absorption, scattering, and other losses in the laser material reduce the transmission efficiency of light within the cavity. Particularly for high-power lasers, the heat generated by material loss can lead to temperature rise, further exacerbating losses.

- Material Aging: With increasing usage time, laser materials undergo aging, and their performance degrades. For example, defects may occur in the active region of semiconductor lasers, resulting in reduced output power.

2. Operating Conditions:

- Temperature: Temperature significantly affects the gain characteristics of laser materials and the performance of optical components. Increased temperature leads to reduced gain coefficients and increased losses, thereby lowering transmission efficiency. Effective temperature control is crucial for improving laser efficiency.

- Pump Power/Operating Current: Pump power or operating current is the energy source for exciting the laser medium. Insufficient pump power or operating current fails to achieve adequate gain, while excessive pump power or operating current leads to issues such as overheating and nonlinear effects, reducing efficiency.

- For semiconductor lasers, the magnitude of the operating current also affects the output power and efficiency of the laser.

3. Laser Structure Design:

- Cavity Design: The design of the resonant cavity (such as cavity length and mirror curvature) affects the number of round trips and losses of light within the cavity. Optimized cavity design can reduce losses and improve output power.

- Optical Components: The quality and design of optical components within the laser (such as mirrors and lenses) affect the transmission efficiency of light. High-reflectivity mirrors and low-loss lenses can improve the transmission efficiency of light within the cavity.

- Coupling Efficiency: The coupling efficiency of laser output (i.e., the proportion of laser output from the cavity) affects the output power of the laser.

4. Optical Device Perfection:

- Mirrors, Collimators, etc.: If the internal optical devices of the laser, such as mirrors and collimators, are poorly designed or installed, it may result in incomplete energy conversion, affecting the output power.

- Beam Sharing: In coupled optical paths with beam sharing, even minor positional deviations of optical components can significantly impact the coupling efficiency of single-mode lasers into optical fibers.

5. Optical Fiber Coupling:

- Optical Fiber End-Face Quality: The cleanliness and smoothness of the optical fiber end-face affect the coupling efficiency of the laser to the optical fiber. Clean and smooth end-faces can reduce losses during the coupling process.

- Coupling Method: Different optical fiber coupling methods (such as lens coupling and direct coupling) have different coupling efficiencies. Selecting an appropriate coupling method can improve coupling efficiency.

- Optical Fiber Mode Matching: The degree of mode matching between the laser and the optical fiber affects coupling efficiency.

Optimization Strategies for Enhancing Transmission Efficiency in Directly Modulated Lasers

1. Precise Control of Operating Conditions

Temperature Control

- Thermoelectric Coolers (TECs): Utilizing the Peltier effect, TECs can precisely control laser temperature by transferring heat through electric current flow.

- Optimized Temperature Control Circuits: Ensuring precision and stability in temperature control involves using high-accuracy temperature sensors, control algorithms, and effective heat dissipation designs.

- Environmental Considerations: Designing laser systems to account for ambient temperature variations and selecting appropriate TECs and cooling solutions ensure stable performance across different environments.

Pump Source/Drive Circuit Optimization

- Semiconductor Lasers: Optimizing drive circuits for precise and stable current control involves using low-noise, high-stability current sources and minimizing electromagnetic interference.

- Other Laser Types: Optimizing pump sources for precise and stable power control includes using high-stability laser diodes or lamps and ensuring uniform and stable pump light paths.

- Design Considerations: Tailoring pump source/drive circuits to laser characteristics and operational requirements ensures stable output under various conditions.

2. Optimization of Laser Materials and Structural Design

Laser Medium Selection

- High-Gain, Low-Loss Media: Selecting materials with high gain and low loss enhances output power and transmission efficiency. For example, quantum well or quantum dot structures in semiconductor lasers can improve gain coefficients and reduce threshold currents.

- Thermal Properties: Choosing materials with high thermal conductivity and low thermal expansion coefficients minimizes thermal effects on laser performance.

Resonator Design

- Geometric and Optical Parameter Optimization: Enhancing the number of light round trips and output efficiency involves using high-reflectivity mirrors, optimized cavity lengths and curvatures, and anti-reflective coatings.

- Mode Characteristics: Optimizing mode matching improves beam quality and stability.

Optical Component Selection

- High-Quality, Low-Loss Components: Using high-quality mirrors, lenses, and fibers reduces transmission losses.

- Optical Properties: Selecting components with high transmittance, low reflectance, and low scattering enhances beam quality and transmission efficiency.

- Installation Practices: Maintaining clean optical surfaces during installation prevents dust and dirt from affecting performance.

3. Improvement of Fiber Coupling Techniques

Fiber Endface Treatment

- High-Quality Cleaning and Processing: Ensuring clean and smooth fiber endfaces reduces contamination and scratches, improving coupling efficiency. Techniques include plasma cleaning, chemical cleaning, and mechanical polishing.

- Static Control: Preventing static buildup during endface treatment avoids dust and dirt adhesion.

Coupling Method Optimization

- Appropriate Coupling Methods: Selecting suitable methods (e.g., lens coupling, direct coupling) and optimizing parameters (e.g., coupling distance, angle) enhances coupling efficiency. Specialized equipment and software can aid in parameter optimization.

- Fiber and Laser Characteristics: Tailoring coupling methods to specific fiber and laser types ensures optimal coupling effects.

Mode Matching Optimization

- Laser and Fiber Mode Matching: Optimizing mode matching reduces mode mismatch losses. Mode matching devices or optical component adjustments can achieve this.

- Laser and Fiber Mode Properties: Selecting appropriate mode matching schemes based on laser and fiber characteristics ensures optimal coupling.

4. Enhancement of Optical Device Perfection

- Minimizing Positional Deviations: High-Precision Installation: Reducing minor positional deviations of optical components through precise installation and stable optical mounts prevents beam misalignment and improves coupling efficiency and output power.

- Optical Path Optimization: Reducing the number of optical components in complex paths minimizes losses.

5. Optimization of Heat Dissipation Design

- Importance of Heat Dissipation: Effective heat dissipation lowers laser operating temperatures, enhancing transmission efficiency and stability. Utilizing heat sinks, fans, and optimized heat paths ensures efficient heat removal.

- Heat Dissipation Methods: Various methods, such as heat sinks, air cooling, water cooling, and thermoelectric cooling, can be employed based on laser power and application environments to maintain stable performance.

In conclusion, the transmission efficiency of directly modulated lasers is influenced by a combination of factors. By precisely controlling operating conditions, optimizing material and structural design, improving optical fiber coupling technology, and enhancing optical device perfection, the transmission efficiency of lasers can be effectively improved. As laser technology continues to evolve, the development of new laser materials, efficient coupling techniques, and advanced packaging technologies will further enhance the efficiency and stability of DML lasers, expanding their applications in various high-tech fields.