High-Power Distributed Feedback (DFB) Lasers: Unlocking New Possibilities

Lasers have revolutionized numerous fields, from telecommunications and manufacturing to medicine and scientific research. They generate a coherent, highly directional beam of light through a process called stimulated emission. Distributed Feedback (DFB) lasers are a specific type of laser known for their exceptional properties, including single-mode operation, narrow spectral linewidth, and high stability. This article explores the world of high-power DFB lasers, delving into their inner workings, the challenges of achieving high power, and the exciting applications they enable.

Understanding DFB Lasers

A DFB laser shares the basic structure of most semiconductor lasers. It consists of a p-n junction, where p and n represent regions doped with different electrical charges. When an electrical current is applied, electrons and holes are injected into the active region, a layer of material designed to stimulate light emission. As these electrons and holes recombine, they release energy in the form of photons. However, in a Fabry-Perot laser (the most common type), these photons can bounce back and forth between the mirrored ends of the cavity, leading to multiple light modes with slightly different wavelengths.

DFB lasers address this issue by incorporating a distributed Bragg reflector (DBR) within the laser cavity. This DBR typically takes the form of a grating etched into the waveguide, a region that confines the light path. The grating acts like a series of tiny mirrors, reflecting a specific wavelength of light back and forth within the cavity. This selective reflection provides feedback that favors a single longitudinal mode, resulting in the emission of a highly coherent and narrow-linewidth light beam.

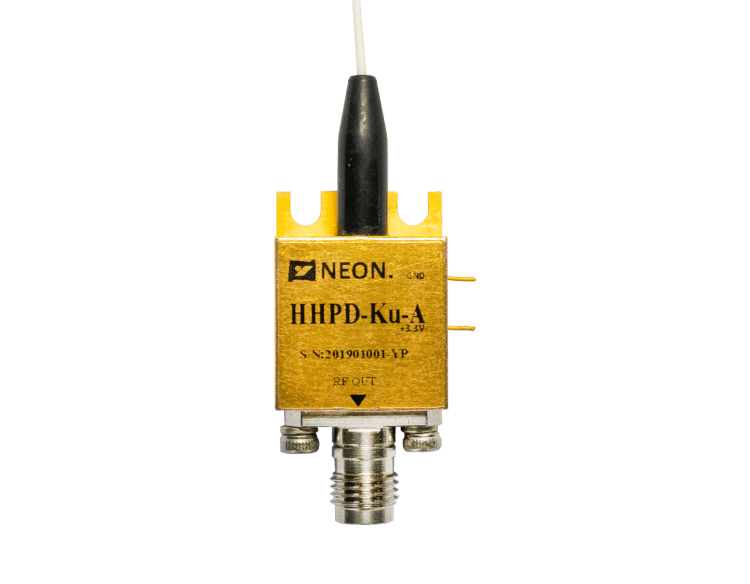

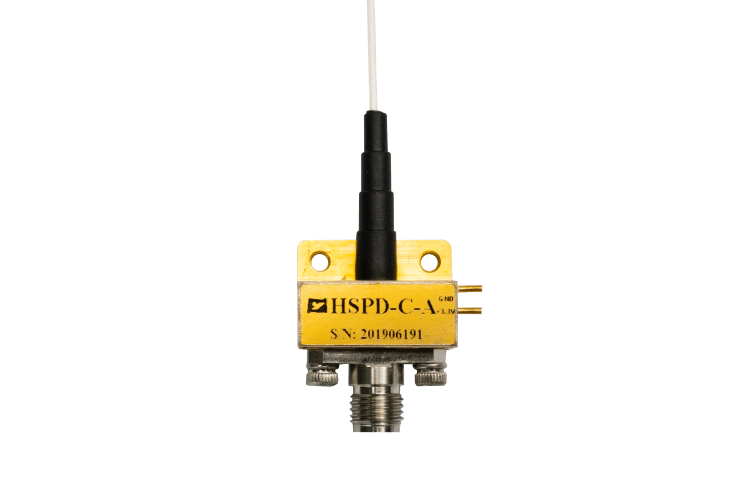

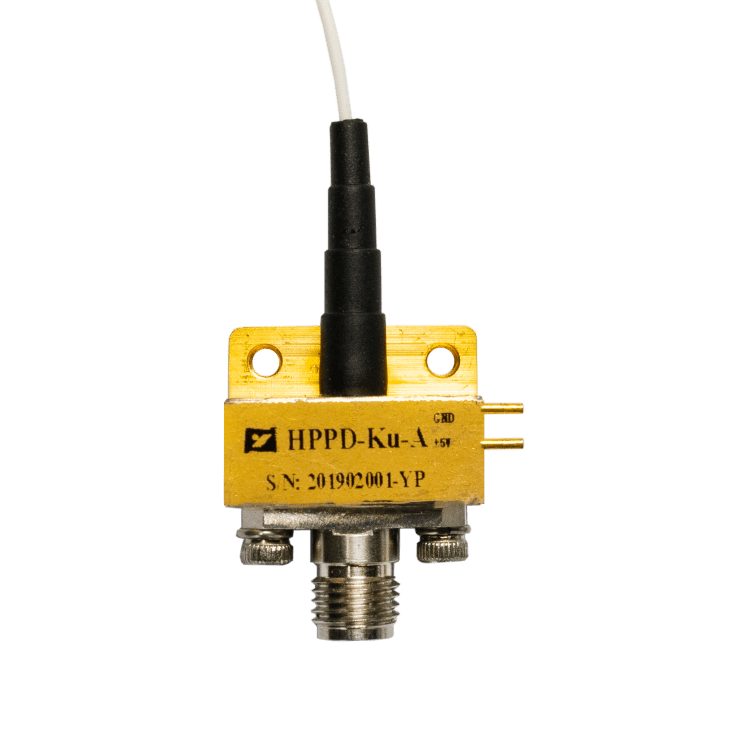

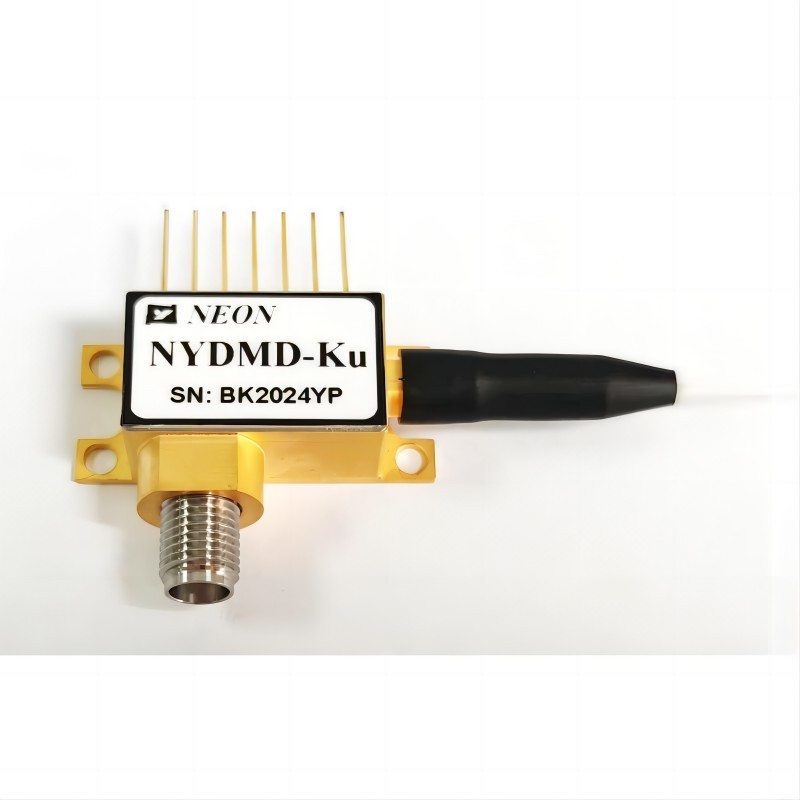

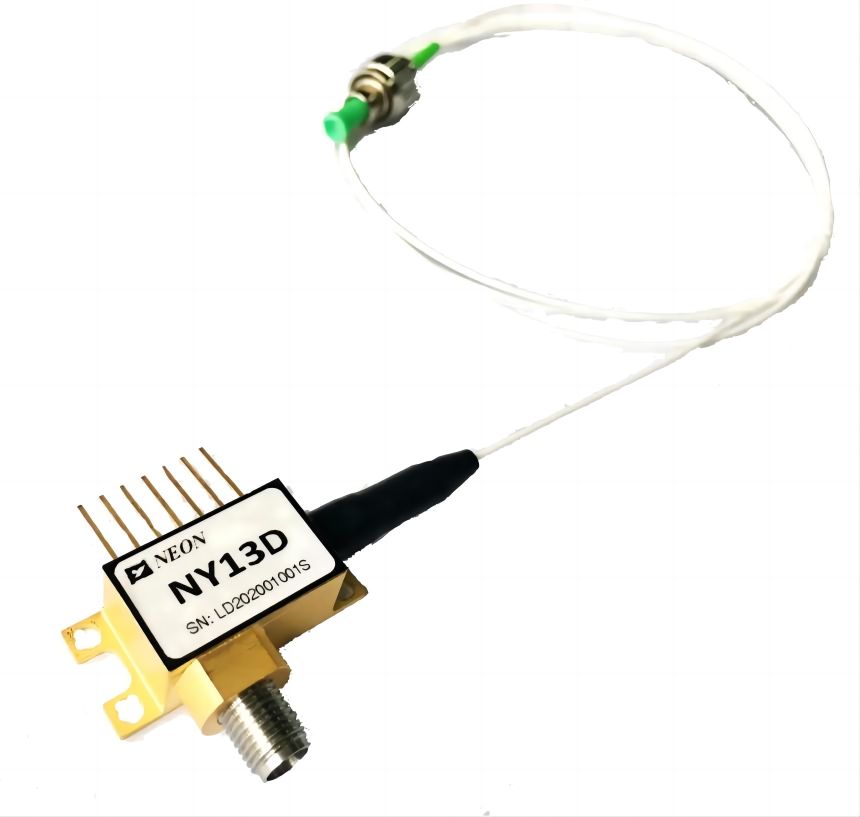

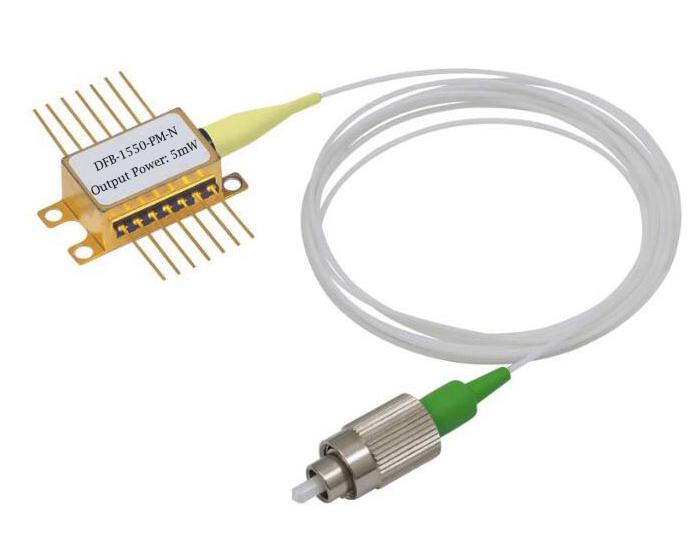

DFB Laser Modules: Packaged Versions of DFB Lasers for Practical Use

While the basic structure of a DFB laser consists of the gain medium and DFB grating, practical applications require a more robust and user-friendly format. This is where DFB laser modules come into play. These modules house the DFB laser chip along with additional components like collimating lenses and electrical drivers within a compact enclosure. This packaging provides several benefits:

- Improved Stability: The module protects the sensitive laser chip from environmental factors, ensuring consistent performance.

- Ease of Use: Standardized connectors and pre-aligned components simplify integration into various systems.

- Enhanced Functionality: Drivers and control electronics within the module enable precise control of the laser’s operating parameters.

High-Power DFB Laser Technologies

While DFB lasers offer excellent spectral purity and stability, achieving high output power presents a significant challenge. As the current through the laser increases, so does the heat generated. Excessive heat can lead to several detrimental effects:

- Increased threshold current: The minimum current required to achieve lasing action increases, making the laser less efficient.

- Wavelength chirp: The laser’s output wavelength can shift with changes in temperature, degrading performance.

- Catastrophic optical damage (COD): At very high power levels, intense light can damage the laser cavity itself.

Therefore, developing high-power DFB lasers requires careful engineering to mitigate these thermal effects. Several approaches are employed:

- Design modifications: Optimizing the DBR grating structure, waveguide geometry, and active region composition can improve heat dissipation and reduce the threshold current.

- Material advancements: Utilizing materials with higher thermal conductivity can help remove heat more effectively. Indium Gallium Arsenide Phosphide (InGaAlP) is a common material choice for high-power DFB lasers operating in the visible and near-infrared range.

- High-power pumping techniques: Techniques like external cavity pumping, where light from another laser source is used to excite the active region, can achieve higher power levels without directly increasing the current through the DFB laser itself.

Unlocking Applications with High-Power DFB Lasers

The unique properties of high-power DFB lasers open doors to various applications across diverse industries. Here are some prominent examples:

- Industrial Processing: High-power DFB lasers are used for material processing tasks such as cutting, welding, and drilling. Their precise beam control allows for clean and efficient cutting of metals, plastics, and other materials.

- Telecommunications: In long-haul optical fiber communication systems, high-power DFB lasers are employed as pump lasers. These lasers provide the intense light source needed to amplify the weak signal on the fiber optic cable, enabling longer transmission distances and higher data rates.

- Biomedical Applications: High-power DFB lasers find use in various medical procedures. In surgery, they can be used for precise tissue ablation in minimally invasive procedures. Additionally, they are employed in laser therapy for treating conditions like skin lesions and vascular diseases.

- Environmental Monitoring: High-power DFB lasers play a role in environmental monitoring systems. They can be used in Light Detection and Ranging (LiDAR) applications, where pulsed laser beams are used to measure distances and create three-dimensional maps of the environment.

DFB Fiber Lasers: A High-Power Evolution

DFB fiber lasers represent a significant advancement in high-power laser technology. These lasers combine the excellent spectral properties of DFB lasers with the inherent advantages of fiber lasers. In a fiber laser, the light propagates through a long optical fiber, allowing for efficient heat dissipation and enabling higher power levels compared to traditional DFB laser diodes. Additionally, the long gain medium in a fiber laser allows for excellent beam quality, further enhancing its utility.

DFB fiber lasers offer several key benefits:

- Excellent Beam Quality: Due to the single-mode operation of DFB lasers and the inherent waveguiding properties of fibers, DFB fiber lasers produce a near-perfect Gaussian beam profile. This translates to a highly focused and controllable beam, crucial for applications like precise cutting and long-distance signal transmission.

- High Efficiency: The efficient light-matter interaction within the fiber core and the reduced thermal effects in a fiber laser design contribute to high overall efficiency. This translates to lower power consumption for achieving desired output power levels.

- Scalability to Even Higher Power Levels: The distributed nature of gain in a fiber laser allows for easier scaling to even higher power outputs compared to traditional DFB laser diodes. By increasing the core diameter or length of the fiber, or employing advanced pumping techniques, fiber lasers can achieve kilowatt (kW) or even megawatt (MW) power levels.

These advantages make DFB fiber lasers ideal for various high-power applications, including:

- Materials processing: DFB fiber lasers can handle high-power cutting, welding, and drilling tasks on a larger scale compared to traditional DFB lasers. Their excellent beam quality and high power density enable precise and efficient processing of thicker and more robust materials.

- Directed Energy Systems: High-power DFB fiber lasers are being explored for directed energy applications, where a concentrated beam of light is used for various purposes. These include laser-based defense systems and industrial material processing requiring extreme power levels.

- Free-Space Laser Communication: DFB fiber lasers are well-suited for free-space laser communication systems, where data is transmitted through the atmosphere using laser beams. Their high power, narrow linewidth, and excellent beam quality enable reliable data transmission over longer distances compared to conventional communication methods.

Conclusion

High-power DFB lasers represent a powerful technology with the potential to revolutionize various fields. By combining the exceptional spectral properties of DFB lasers with innovative design techniques and material advancements, these lasers offer unmatched performance in terms of power, stability, and beam quality. The emergence of DFB fiber lasers further expands the capabilities of high-power lasers, pushing the boundaries of what’s achievable in material processing, telecommunications, and beyond. As research and development in this field continue, we can expect even more exciting applications for high-power DFB lasers in the years to come.