How Distributed Feedback Lasers Shape Modern Technology

Lasers have revolutionized numerous fields by providing a highly controlled source of light with unique properties. Among the diverse types of lasers, Distributed Feedback (DFB) lasers stand out due to their exceptional stability and precision. These characteristics make DFB lasers ideal for demanding applications like telecommunications, spectroscopy, and industrial sensing. This article explains the principles, structure, applications, and benefits of DFB lasers, offering insights into why they are so crucial to modern technology.

What is a Distributed Feedback (DFB) Laser?

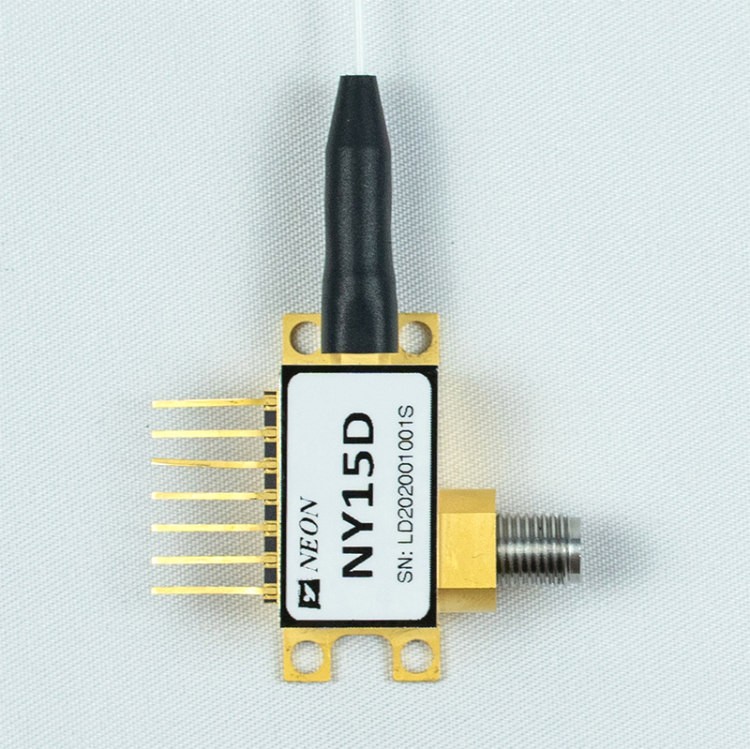

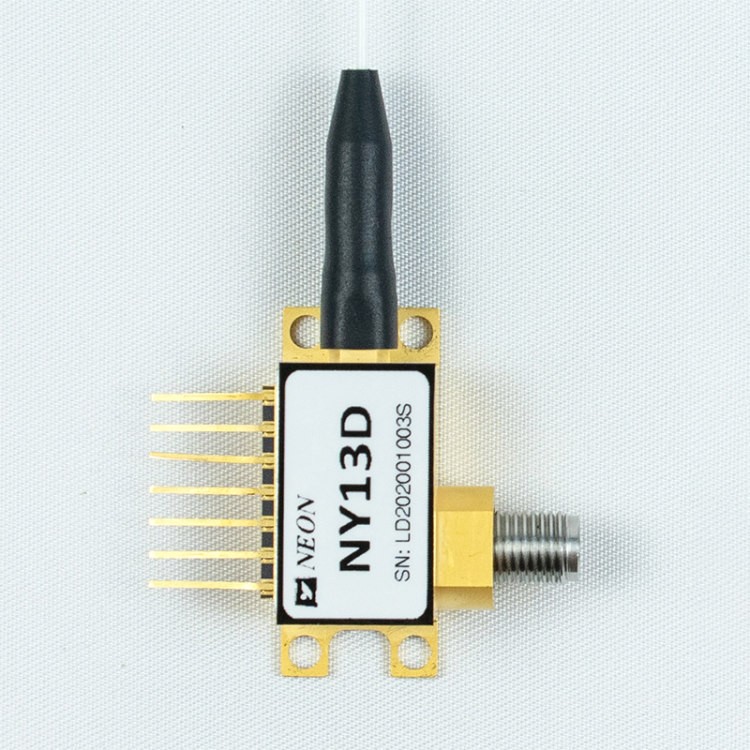

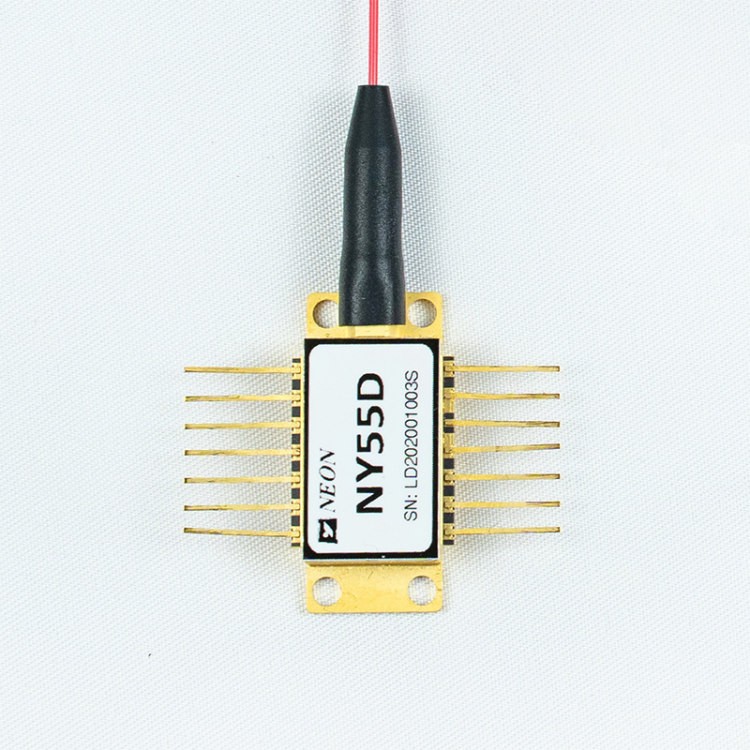

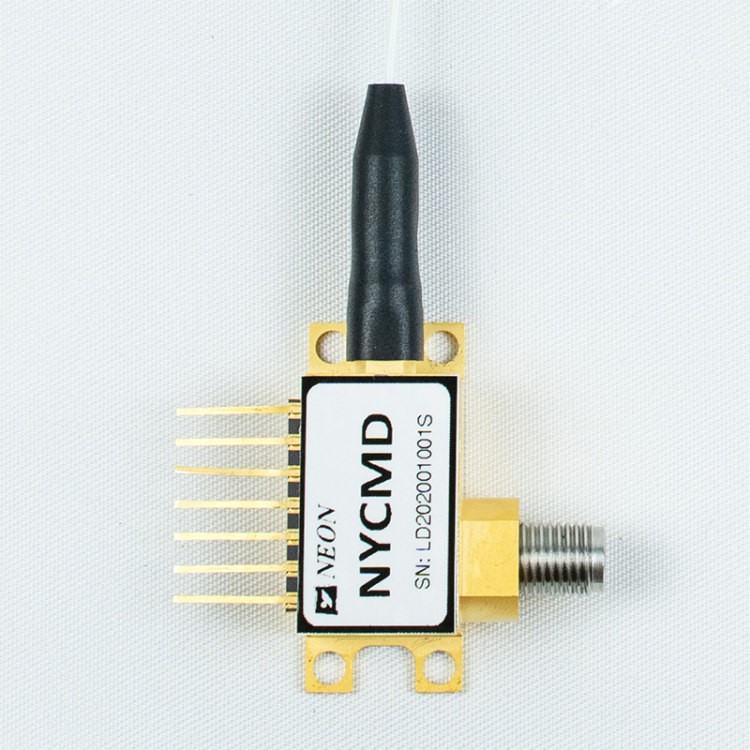

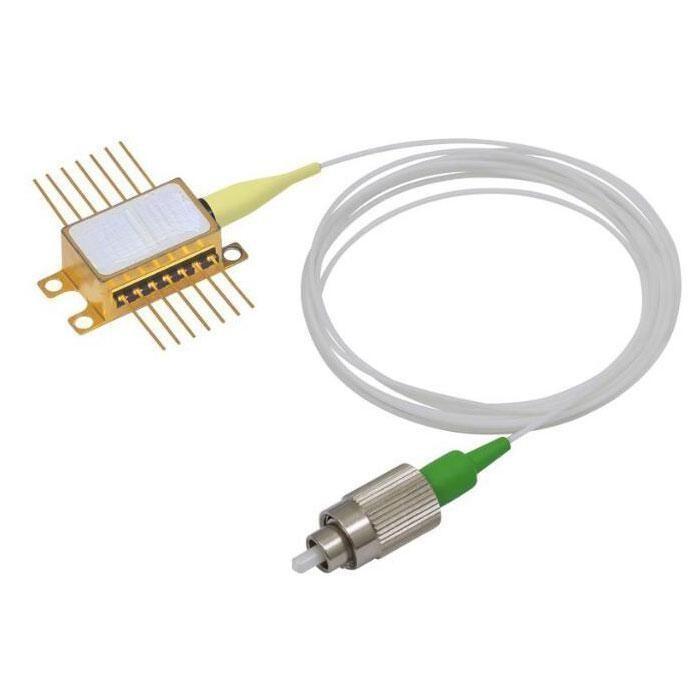

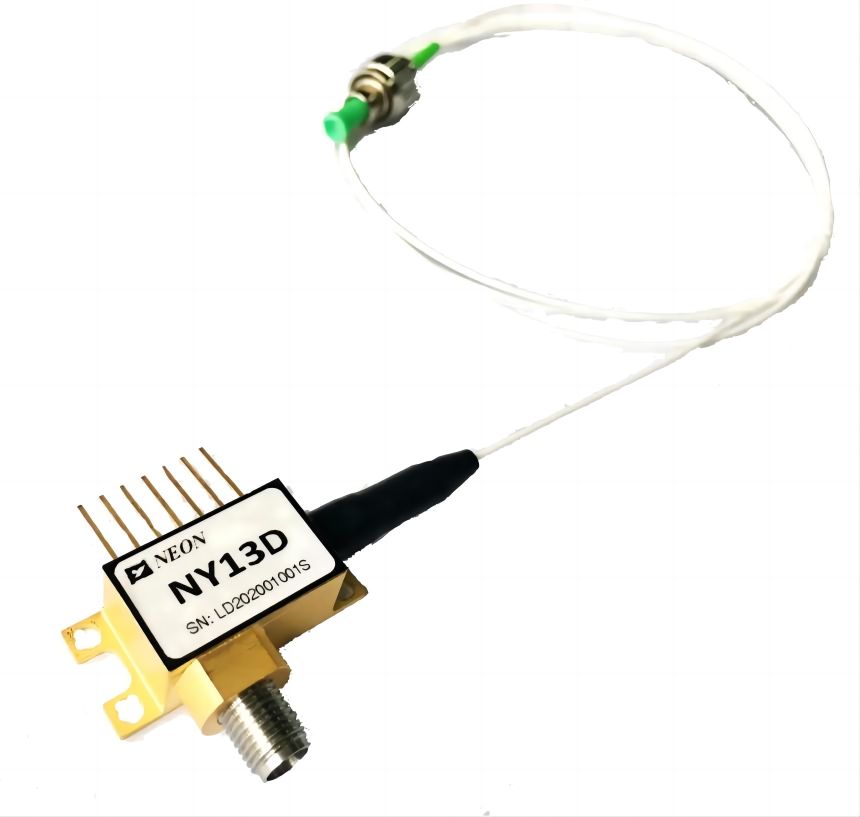

A Distributed Feedback (DFB) laser is a specialized type of semiconductor laser diode that generates light in a single wavelength with high stability. The distinctive feature of DFB lasers is the diffraction grating embedded within the gain medium, which allows them to produce a highly controlled, narrow-linewidth output at a precise wavelength.

Historically, laser technology began with simpler, multimode lasers, but advancements in applications such as fiber-optic communication required more refined solutions. DFB lasers were developed to address this need for single-mode, stable wavelength lasers. They are especially valuable in environments where maintaining a stable output wavelength is critical, such as in long-distance data transmission and sensitive spectroscopic measurements.

Working Principle of DFB Lasers

The working principle of a DFB laser relies on a unique structural component: the Bragg grating. This grating acts as a built-in optical filter that selectively reinforces specific wavelengths within the laser cavity, enabling the laser to operate in a single longitudinal mode, which is highly desirable for many applications.

In a DFB laser, the Bragg grating is periodically embedded in the semiconductor material of the laser cavity. As current passes through the semiconductor, it generates a gain medium where photons are amplified. The Bragg grating reflects only certain wavelengths of light that match the grating period, allowing the laser to achieve a single-mode output while suppressing other modes that could destabilize the signal.

This design leads to a “distributed” feedback mechanism, which is spread across the laser cavity rather than being concentrated at the ends as in Fabry-Perot (FP) lasers. This mechanism contributes to the laser’s single-mode operation, stable wavelength, and high spectral purity, making it well-suited for applications that require reliable, interference-free performance.

Structural Design and Fabrication of DFB Lasers

A DFB laser’s core component is the integrated Bragg grating, which plays a crucial role in determining its spectral properties. The design and fabrication of this grating are critical factors in achieving the desired laser performance.

Grating Design and Fabrication

The grating is typically a periodic structure etched into the semiconductor material, often within the active layer or adjacent to it. The period of the grating, along with the refractive index of the material, determines the wavelength at which the laser operates. By carefully controlling the grating’s dimensions during fabrication, manufacturers can achieve precise wavelength selection.

Key Fabrication Techniques

- Photolithography: This technique is used to pattern the grating structure onto the semiconductor material. A photosensitive material is applied to the surface, exposed to light through a mask, and then developed to create the desired pattern.

- Etching: The exposed areas of the semiconductor are then etched away using chemical or physical processes to form the grating.

Challenges in DFB Laser Fabrication

The fabrication of DFB lasers presents several challenges:

- Precision: The dimensions of the grating must be precisely controlled, as even small variations can significantly impact the laser’s performance.

- Alignment: The grating must be accurately aligned with the active region of the laser to ensure efficient coupling between the light and the grating.

- Material Quality: The quality of the semiconductor material used to fabricate the laser is crucial. Defects or impurities in the material can degrade the laser’s performance.

Due to these challenges, DFB lasers are generally more expensive to manufacture than simpler laser diodes. However, their superior performance and versatility make them indispensable in a wide range of applications.

Key Specifications of DFB Lasers

When evaluating DFB lasers, several key specifications often define their performance and suitability for particular applications. Here are some critical aspects:

| Specification | Description | Significance |

| Output Wavelength | Wavelength of the emitted light in nanometers (nm) | Determines the suitability for specific applications, such as telecommunications (1310 nm or 1550 nm) |

| Output Power | Power of the emitted light in milliwatts (mW) | Influences the range and signal strength in various applications, from short-distance sensing to long-haul telecommunications |

| Linewidth | Spectral width of the emitted light in kilohertz (kHz) | A narrower linewidth indicates higher spectral purity and coherence, crucial for applications like high-resolution spectroscopy and high-speed data transmission |

| Temperature Stability | Ability to maintain wavelength stability over a range of temperatures | Ensures reliable performance in varying environmental conditions, especially critical for telecommunications and sensing applications |

Applications of DFB Lasers

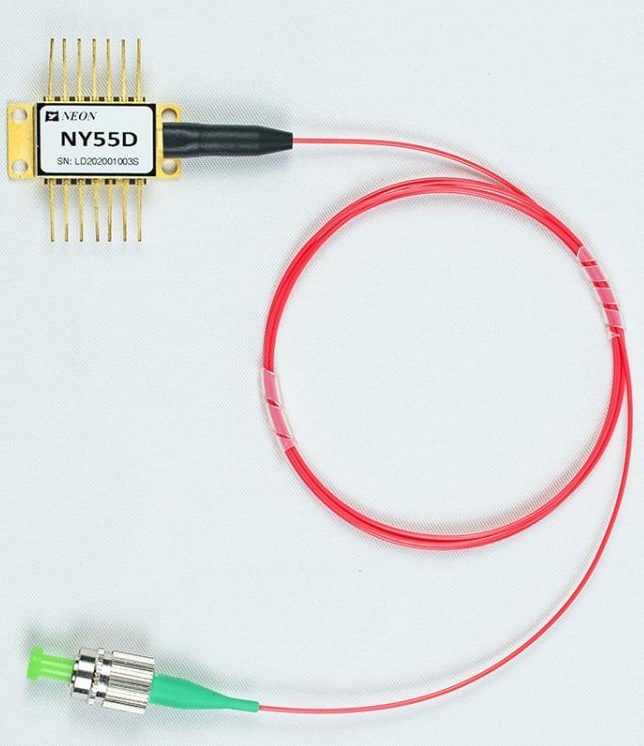

Thanks to their stability, precision, and single-mode output, DFB lasers are widely used across various fields. Some of the most common applications include:

| Industry | Application | Role of DFB Laser |

| Telecommunications | Fiber-optic communicationsWavelength-Division Multiplexing (WDM) | Enables efficient long-distance data transmission and increased bandwidth capacity through stable wavelength and narrow linewidth |

| Spectroscopy and Sensing | Gas sensing, environmental monitoringHealthcaremanufacturing | Provides precise wavelength selection and narrow linewidth for accurate molecular detection and analysis |

| Medical and Industrial | Optical coherence tomography (OCT)lidar systems measurement and analysis equipment | Enables precise targeting, accurate distance measurements, and stable laser sources for various industrial processes |

Advantages of DFB Lasers Over Other Laser Types

When compared to other laser types, such as Fabry-Perot (FP) and Distributed Bragg Reflector (DBR) lasers, DFB lasers offer several distinct advantages:

Comparison with Fabry-Perot (FP) Lasers

- Single-Mode Operation: Unlike FP lasers, which produce multiple longitudinal modes, DFB lasers emit light at a single, well-defined wavelength. This ensures high spectral purity and coherence, making them suitable for applications requiring precise frequency control.

- Improved Temperature Stability: DFB lasers exhibit superior temperature stability compared to FP lasers. This means that their output wavelength remains stable even in fluctuating temperature environments, critical for applications like telecommunications.

Comparison with Distributed Bragg Reflector (DBR) Lasers

- Simpler Design and Improved Stability: DFB lasers have a simpler design compared to DBR lasers, as the grating is integrated within the active region. This often leads to better long-term stability and reduced manufacturing complexity.

- Enhanced Wavelength Control: While DBR lasers offer some wavelength tunability, DFB lasers generally provide more precise and stable wavelength control. This is due to the distributed nature of the feedback mechanism in DFB lasers.

Key Advantages of DFB Lasers

- High Spectral Purity and Coherence: The single-mode operation of DFB lasers ensures a high degree of spectral purity and coherence, making them ideal for applications requiring precise frequency control.

- Excellent Temperature Stability: DFB lasers maintain stable output wavelength across a wide range of temperatures, ensuring reliable performance in various environments.

- Precise Wavelength Control: The distributed feedback mechanism in DFB lasers enables precise wavelength control, making them suitable for applications requiring specific wavelength emission.

- High Reliability and Long Lifespan: DFB lasers are known for their high reliability and long lifespan, reducing maintenance costs and downtime.

These advantages make DFB lasers indispensable in various fields, including telecommunications, optical sensing, spectroscopy, and medical applications.

Common Questions about DFB Lasers

- Why are DFB lasers preferred in fiber-optic communication?

The single-mode output and wavelength stability of DFB lasers reduce signal degradation over long distances, making them essential for high-speed, high-capacity fiber-optic communication.

- What makes DFB lasers more expensive than other types?

The manufacturing process for DFB lasers, including the precise fabrication of the Bragg grating, adds complexity and cost. However, this precision is necessary for their stability and performance.

- Can DFB lasers be tuned, and if so, to what extent?

While DFB lasers are designed for stable single-wavelength output, they can be tuned over a small range by adjusting the operating temperature or current. However, they are not as tunable as external cavity lasers, which are designed specifically for broader tunability.